- News

- Subscribe

Get full access to GreenPort content

Including, full access to our news archive, podcasts, webinars and articles on innovations and current trends to increase port sustainability.

- Expert analysis and comment

- Unlimited access to in-depth articles and premium content

- Full access to all our online archive

Alternatively REGISTER for website access and sign up for email alerts

- Events

GreenPort Congress & Cruise

Green Ports & Shipping Congress

Coastlink Conference

GreenPort Congress Oceania

GreenPort Congress is a meeting place for the port community to discuss and learn the latest in sustainable environmental practice. It offers ways to reduce their carbon foot print and be more sensitive to environmental considerations, both of which are vital to future success. The Green Ports & Shipping Congress will identify and prioritise the areas that ports-based organisations and shipping companies need to collaborate on to reduce emissions. Coastlink is a neutral pan-European network dedicated to the promotion of short sea and feeder shipping, and the intermodal transport networks through the ports that support the sector. It is a place for industry professionals to meet and discuss future innovation, economic and environmental considerations – and develop partnerships that will help build a sustainable future. Greenport Congress Oceania will bring together environmental managers from port authorities, terminal operators, shipping lines and logistics operators to learn about the latest sustainable developments and environmental practices in the Oceanic region and beyond. Visit the GPC Website Visit the GPSC Website Visit the Coastlink Website Visit the GPO Website

Cavotec inks major shorepower deal

2024-04-25T11:40:00+01:00

Cavotec and a global shipping company have inked a deal worth US$5m to supply PowerFit shore power units

California looks to mobile port emissions capture

2024-04-24T14:50:00+01:00

EXCLUSIVE: A big vision for Hong Kong’s green cruise hub

2024-04-23T13:30:00+01:00By Michele Witthaus

Joined up thinking on methanol storage

2024-04-23T12:52:00+01:00

A new European hydrogen corridor

2024-04-23T12:33:00+01:00

Teaming up on alternative fuels

2024-04-22T13:20:00+01:00

Decarbonisation report sets out challenges

2024-04-19T12:49:00+01:00

Biofuel push in Singapore

2024-04-18T07:45:00+01:00

EXCLUSIVE: UNCTAD project boosts Africa’s smart ports’ dream

2024-04-16T13:33:00+01:00By Shem Oirere

Konecranes electrifies the Bahamas

2024-04-16T12:48:00+01:00

- Previous

- Next

Mercator Media Ltd

Sponsored by Mercator Media

Sign up for free

Receive unlimited GreenPort content today!

Including, full access to our news archive, podcasts, webinars and articles on innovations and current trends to increase port sustainability.

Cavotec inks major shorepower deal

2024-04-25T11:40:00+01:00

Cavotec and a global shipping company have inked a deal worth US$5m to supply PowerFit shore power units

California looks to mobile port emissions capture

2024-04-24T14:50:00+01:00

A novel form of mobile port emissions capture is taking place in California

EXCLUSIVE: A big vision for Hong Kong’s green cruise hub

2024-04-23T13:30:00+01:00By Michele Witthaus

The social aspects of sustainability are at the heart of Kai Tak Cruise Terminal’s ethos

California looks to mobile port emissions capture

2024-04-24T14:50:00+01:00

A novel form of mobile port emissions capture is taking place in California

EXCLUSIVE: A big vision for Hong Kong’s green cruise hub

2024-04-23T13:30:00+01:00By Michele Witthaus

The social aspects of sustainability are at the heart of Kai Tak Cruise Terminal’s ethos

A new European hydrogen corridor

2024-04-23T12:33:00+01:00

The corridor will link Spain and The Netherlands

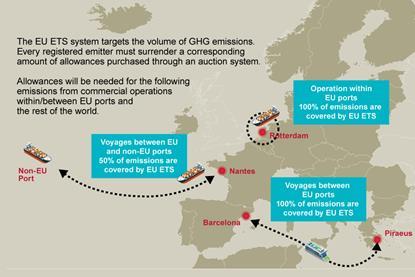

EXCLUSIVE: The implementation and competitiveness challenge

2024-03-19T13:03:00+00:00By Isabelle Ryckbost

EXCLUSIVE: How will shipping implement all the new emissions regulation coming into force?

Unifying the way we all count emissions

2023-12-13T16:41:00+00:00By Isabelle Ryckbost

Europe is looking to unify the way that freight and passenger transport and hubs count emissions

Overcoming grid power issues using batteries

2023-11-16T10:12:00+00:00

Battery energy storage systems could help ports overcome grid constraints

Ports need ‘clear strategy and vision’ for sustainability

2023-05-05T11:08:00+01:00

A clear vision and strategy for sustainability and decarbonisation is critical if ports are to meet net zero targets

We can and must decarbonise logistics: Maersk

2023-05-05T11:05:00+01:00

Day two of the Coastlink Conference opened with a stark message about the climate emergency

Sustainability and decarbonisation never far from Coastlink discussions

2023-05-05T10:58:00+01:00

Nick Lambert opens two days of Coastlink conference with a climate-change call to arms

Interested in speaking at GreenPort Congress and Cruise 2024?

2024-04-17T14:24:00+01:00

Heading for HAROPA PORT

2024-04-16T11:04:00+01:00

Positive feedback for GreenPort Congress & Cruise 2023 in Lisbon

2023-11-03T10:25:00+00:00

Did You Miss It? – 60 Papers and Presentations Plus On Demand Viewing Now Available

2023-11-03T09:46:00+00:00

Greenport Port Tour Organised by Port of Lisbon

2023-10-23T12:11:00+01:00

Renewables and alternative energies: ambitions and challenges

2023-10-23T10:27:00+01:00